Space Qualified Axially Grooved Aluminium Ammonia Heat Pipe

| Material | Extrusion: Aluminium Alloy AA 6063 - T6 Components: Aluminium Alloy AA 6061 - T6 |

|---|---|

| Wicking System | Axial Grooves (Extruded Types) |

| Working Fluid | Ultra-pure anhydrous Ammonia (purity > 99.99994%) |

| Temperature Range | -40°C to 80°C (operating) and -75°C to 80°C (non-operating) |

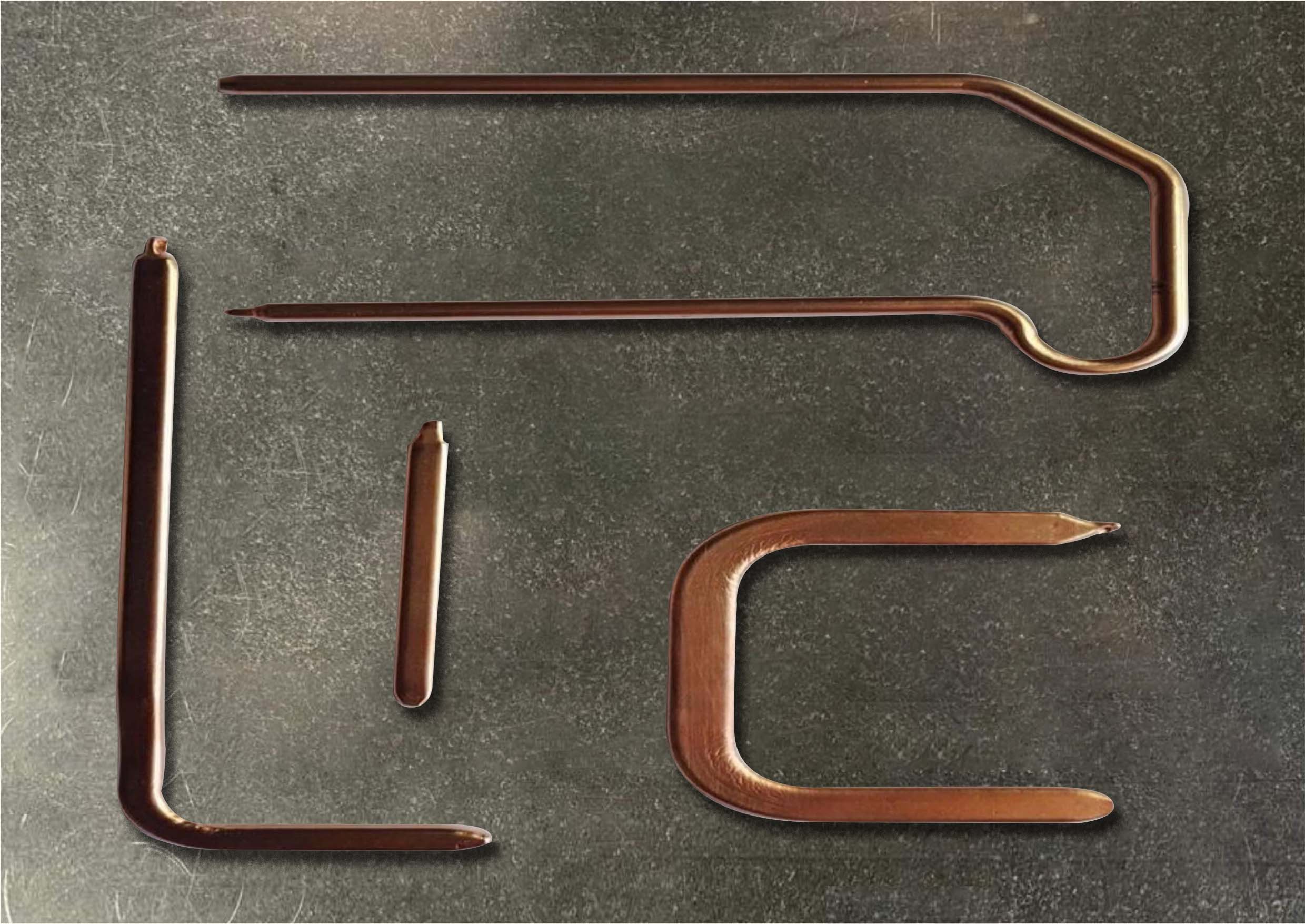

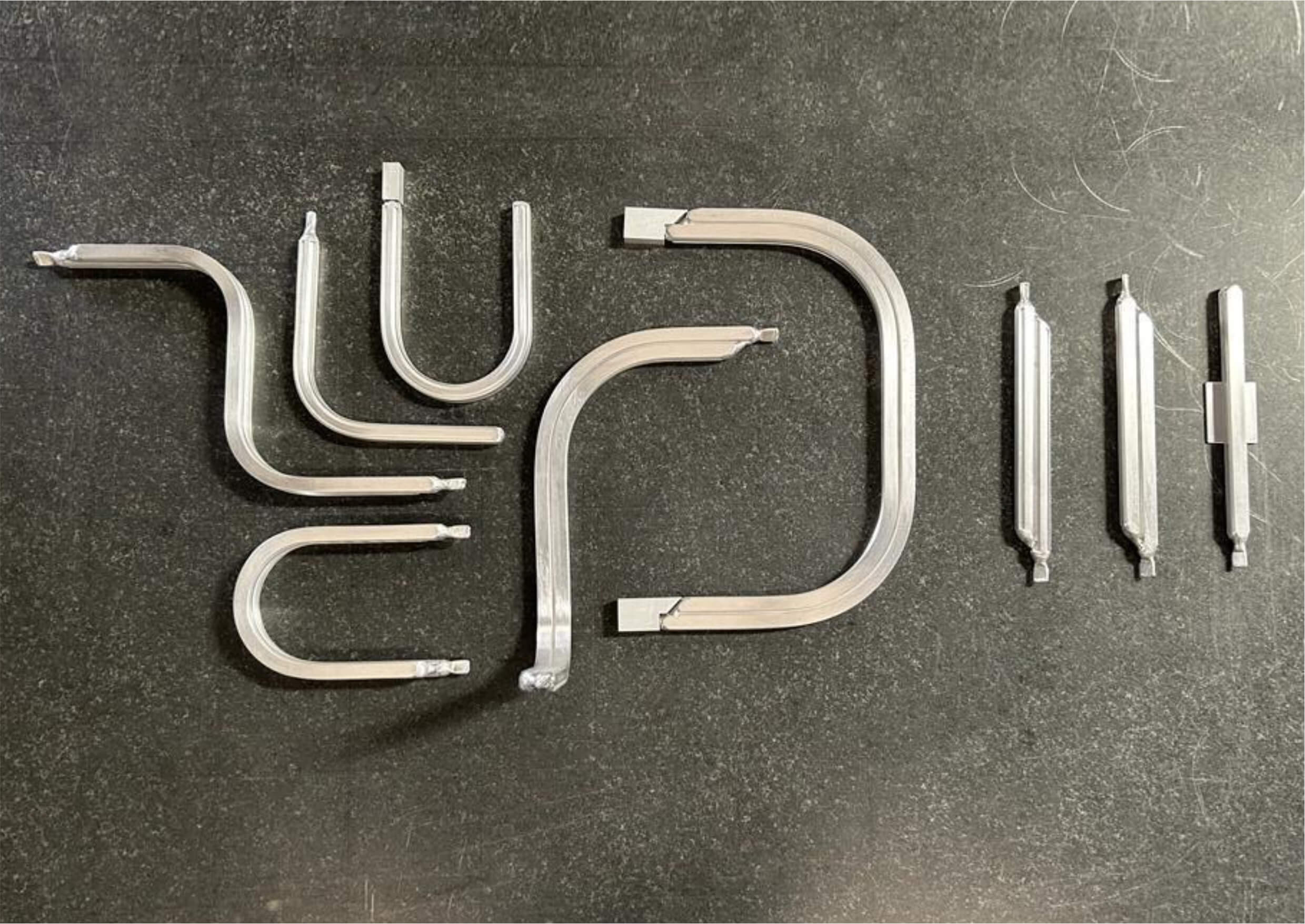

| Types | Single Channel & Dual Channel |

| Length | ~0.2 m to ~3 m (200 mm to 3000 mm) |

| Shapes | Straight & Bent 1 to 5 bends | Bend angle: 1° to 180° |

| Cross Section | 12.5 mm × ~12.5 mm for single channel heat pipe | ~12.5 mm × ~25 mm for dual channel heat pipe |

| Dimensional Tolerance | Height 50 microns Width 200 microns |

| Welding Technique | Tungsten Insert Gas Welding |

| Helium Leak Rate | Less than 1 × 10⁻⁸ mbar l/s |

| External Surface Finish | < 200 g/m for single channel heat pipe including working fluid | < 400 g/m for dual channel heat pipe including working fluid |

| Nominal Mass Unit Per Length | Flatness: ≤ 0.15mm in a length of 200 mm & ≤ 0.2 mm for full length of heat pipe (out of plane) Roughness: ≤ 0.01mm | Parallelism: ≤ 0.2mm /1000 mm | Straightness: ≤ 0.5mm / 1000 mm (in-plane) |

| Pressure | Burst: ≤ 250 kg/cm² | Proof: ≤ 190 kg/cm² |

| Heat Transport Capability | More than 150 W/m per channel @ 20°C | More than 120 W/m per channel @ 60°C (≤ 5 % performance degradation per bend) |

| Non-Condensable Gas Length | Less than 5 mm at -40°C operating temperature after working fluid charging | Less than 15 mm at -40 °C operating temperature after acceptance tests |

| Life | 15 years in Space with an average operating temperature of +50°C (excluding 5 years of ground storage) |